Labor-intensive processes and inconsistent quality plague traditional resin grinding wheel production. Cosmos Press addresses these challenges as specialized hydraulic press machine suppliers for resin grinding wheel production, delivering fully automated lines that merge precision, speed, and reliability.

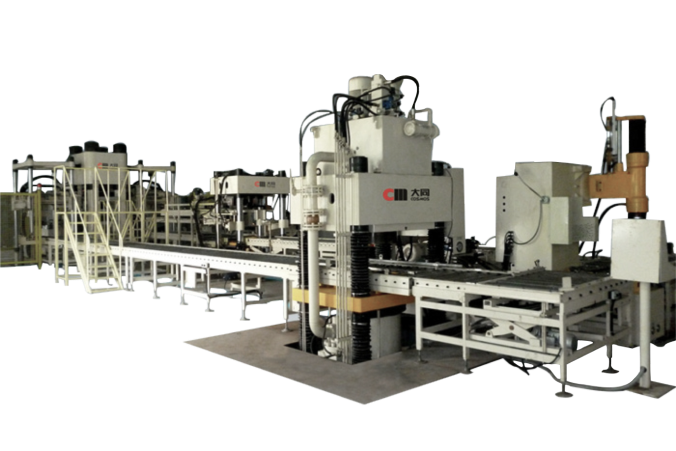

Integrated Press Systems for Flawless Workflow

The automated line hinges on four synchronized hydraulic presses, each engineered for a critical phase. A packing hydraulic press pre-compacts raw materials, while the pre-press hydraulic press shapes the wheel’s initial form. Dual hot-press hydraulic presses then execute the final curing under controlled heat and pressure—doubling output without sacrificing uniformity. Crucially, a demoulding hydraulic press ejects finished wheels intact, minimizing breakage. This orchestrated sequence, managed by intelligent conveying devices, positions Cosmos Press as visionary customized machine manufacturers for resin grinding wheel production.

Thermal Innovation for Superior Product Integrity

Beyond pressing, temperature management defines wheel durability. Cosmos Press integrates a finished thermal insulation box to stabilize wheels during cooling, preventing warping or cracking. Simultaneously, a mold cooling device rapidly chills used molds, while the mold preheating device prepares subsequent molds—slashing cycle times by 40%. This thermal ecosystem ensures every excellent press for grinding wheels operates at peak efficiency, yielding wheels with consistent density and abrasion resistance.

Conclusion

For manufacturers prioritizing scale and precision, Cosmos Press delivers turnkey automation. Their expertise as hydraulic press machine suppliers for resin grinding wheel production transforms high-volume output, blending German-engineered presses for grinding wheels with bespoke thermal controls. Partnering with these customized machine manufacturers guarantees competitive advantage: flawless wheels, lower rejects, and ROI-driven innovation.