The combination of high-precision 3D laser scanning and artificial intelligence is a game-changer for metrology and design. In the past, 3D scanning and reverse engineering—turning a physical object into a clean, editable digital model—was a complicated process that required a lot of manual work and subjective interpretation. AI is now acting as a smart partner, automating complicated data processing tasks and finding geometric meaning at an unmatched speed. This change means that modern engineers, 3D artists, and designers will no longer have to deal with bottlenecks, and the process of turning a physical object into a final product will go much faster. The technology makes it easier for many service bureaus and end-users to get started on projects because it cuts down on the time and specialized knowledge needed to finish them. Companies like 3DeVOK build these AI-powered tools right into their products, setting a new standard for speed and accuracy in the digital thread that links capture, design, and manufacturing.

Automating the Process of Preparing Complex Scan Data

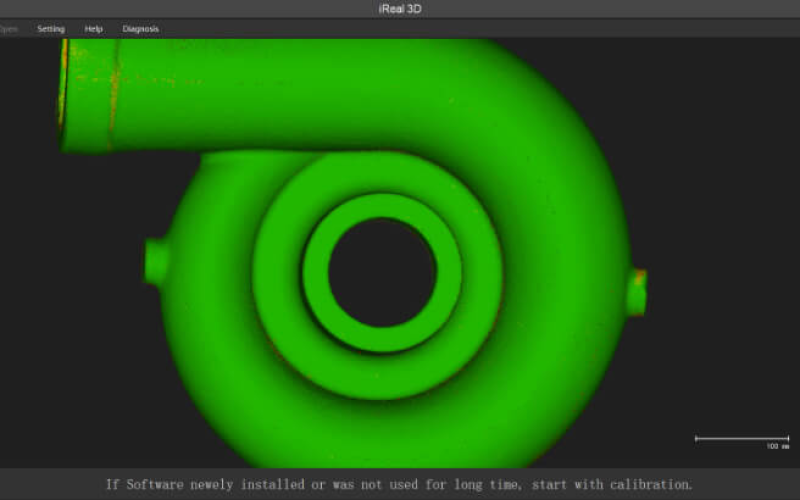

The first problem with reverse engineering 3D scanning is dealing with the raw data, which is often messy, broken up, or noisy because of the way it was captured. Technicians used to have to spend a lot of time manually filtering outliers, aligning multiple scan passes (registration), and filling in holes in the mesh. This repetitive cleanup phase was often the part of the process that took the longest. AI is proving to be very useful here because it uses advanced machine learning algorithms to tell the difference between sensor noise and real geometric form. The system can automatically do mesh optimization, which smooths out small flaws without losing important sharp edges. This is a difficult balance to strike by hand.

For tasks that involve a lot of 3D scanning and reverse engineering, AI’s ability to quickly and accurately register different scans and combine them into one cohesive 3D Scan Model cuts down on preprocessing time by a huge amount. The AI doesn’t need to pick points or align features by hand; it can instantly find corresponding physical features in different datasets and stitch them together with metrology-grade accuracy. This smart automation makes it easier for end users, 3D artists, and schools to get started, so they can focus right away on high-value design work instead of cleaning up data over and over again. AI makes sure that the first mesh is clean and geometrically sound, which sets the stage for all the reverse engineering and 3D printing preparation that comes after it.

AI-Powered Feature Recognition and Intent Analysis

The most important part of 3D scanning reverse engineering is interpretation. This is the mental challenge of figuring out what the original designer meant by turning millions of static mesh points into design parameters that can be changed. AI helps this process by automating the extraction of geometric features. The system can quickly find areas in a dense point cloud that match common engineering primitives, like perfect planes, true cylinders, or circular holes. This is true even if the physical object is worn or slightly bent from manufacturing stress. The AI finds the best mathematical primitive and its exact size, taking into account noise and imperfections in the real world.

Engineers and reverse engineering experts need to be able to make this jump from static data to meaningful, editable parameters. It lets them skip the slow, manual sketching and fitting process that used to be the norm. AI also helps with the semi-automatic creation of control lines and surfaces for complicated, organic shapes that are common in cars, medical devices, and consumer goods. The system can smartly help you make high-quality NURBS surfaces that follow the complex shapes of the scan data smoothly and accurately. This intelligence speeds up the process of making the parametric CAD model. This makes sure that the digital reconstruction is not just a passive copy but an intelligent, editable design that can be changed, simulated, or made using CNC machining.

Accelerating Validation and Parametric Modeling with AI

Integrating AI into 3D scanning and reverse engineering significantly accelerates the validation of CAD models against original scan data. Through AI-enhanced metrology, real-time deviation analysis provides immediate visual feedback, allowing technicians to iteratively refine models without delay.

This continuous verification shortens approval cycles and enhances confidence in the final output—particularly crucial for 3D printing and custom manufacturing, where geometric accuracy ensures proper fit and function. AI further supports seamless data export to universal CAD formats, preserving model integrity for downstream processes.

By embedding AI throughout its software, 3DeVOK streamlines the entire reverse engineering workflow—from mesh processing to CAD certification—reducing reliance on specialized manual input. The result is a more efficient and accessible digital thread, empowering global technicians and engineers to transform physical objects into editable digital assets with unprecedented speed and reliability.