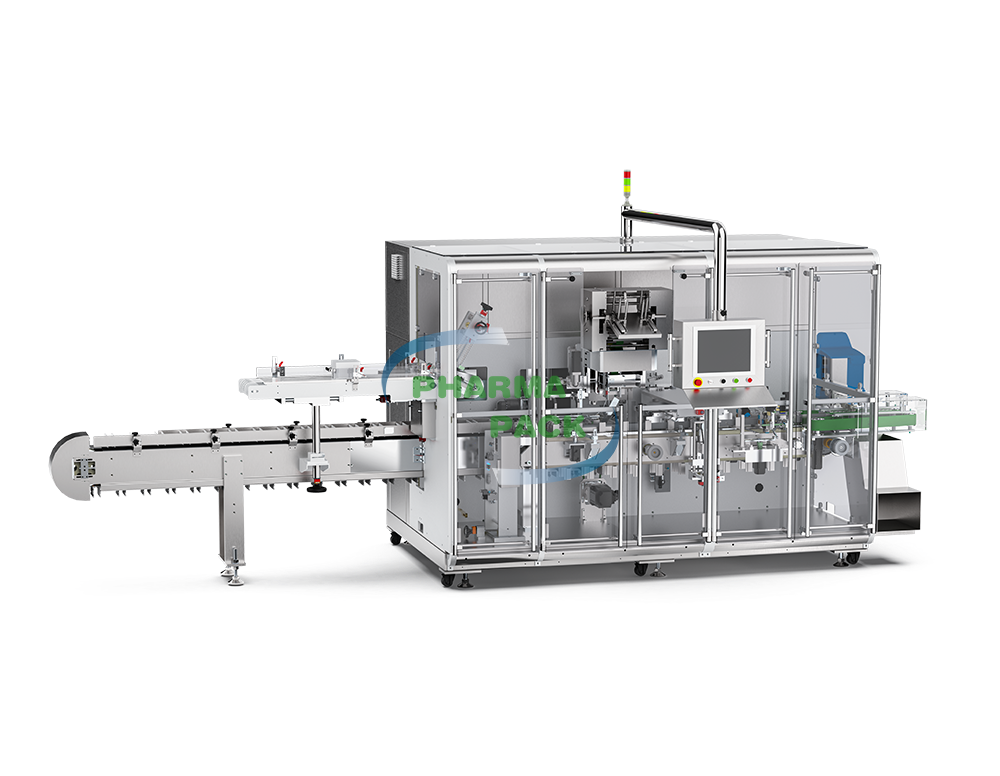

A persistent operational consideration in pharmaceutical packaging involves the duration of machine changeovers when switching product formats. Extended adjustments curtail production time and affect overall line output. The Pharmapack LFBI-10 Intermittent Horizontal Cartoner incorporates a specific feature to address this: a digital display handwheel. This component is central to the machine’s tool-free quick adjustment system, providing a direct method for operators to reconfigure the pharmaceutical cartoning machine with both speed and precision.

Direct Mechanical Interface for Precision Adjustment

The digital display handwheel replaces traditional, tool-dependent mechanical stops and scales. On the LFBI-10 horizontal cartoning machine, an operator can grip and turn the handwheel to adjust critical components, such as the guide rails that determine the carton size the machine will accommodate. Each rotation of the handwheel corresponds to a precise mechanical movement within the machine. The integrated digital screen provides real-time, numerical feedback on the exact position or dimension, removing the guesswork associated with manual rulers or etched gauges. This allows for adjustments to be made accurately and repeated consistently for a given product format.

Supporting Structure for Simplified Access

The efficiency of this adjustment system is enhanced by the machine’s overall architecture. The LFBI-10’s “Balcony” structure, where drive components are mounted to the side of the conveying mechanism, provides unobstructed access to the adjustment points. This clear workspace allows an operator to reach the digital display handwheel and other quick-release mechanisms without contending with machinery housings or internal components. This design philosophy ensures that the promised tool-free quick adjustment is not hindered by poor accessibility, a consideration for any modern pharmaceutical cartoning machine.

Implications for Operational Throughput

The combined effect of tool-free adjustments and clear access is a substantial reduction in changeover time. An operator can execute size changes on this horizontal cartoning machine without fetching tools, manually measuring gaps, or conducting multiple test runs to achieve the correct setting. The digital feedback guarantees the setting is correct before production resumes. For facilities managing numerous product SKUs, this capability translates to more batches run per shift and enhanced responsiveness to production scheduling demands.

In conclusion, the digital display handwheel on Pharmapack’s LFBI-10 represents a focused engineering solution for minimizing non-productive changeover time. It provides a direct, accurate, and repeatable method for reconfiguring the horizontal cartoning machine. This feature, supported by the machine’s accessible structure, underscores a commitment to designing equipment that supports the operational efficiency and flexibility required by experienced packaging professionals in the pharmaceutical industry.