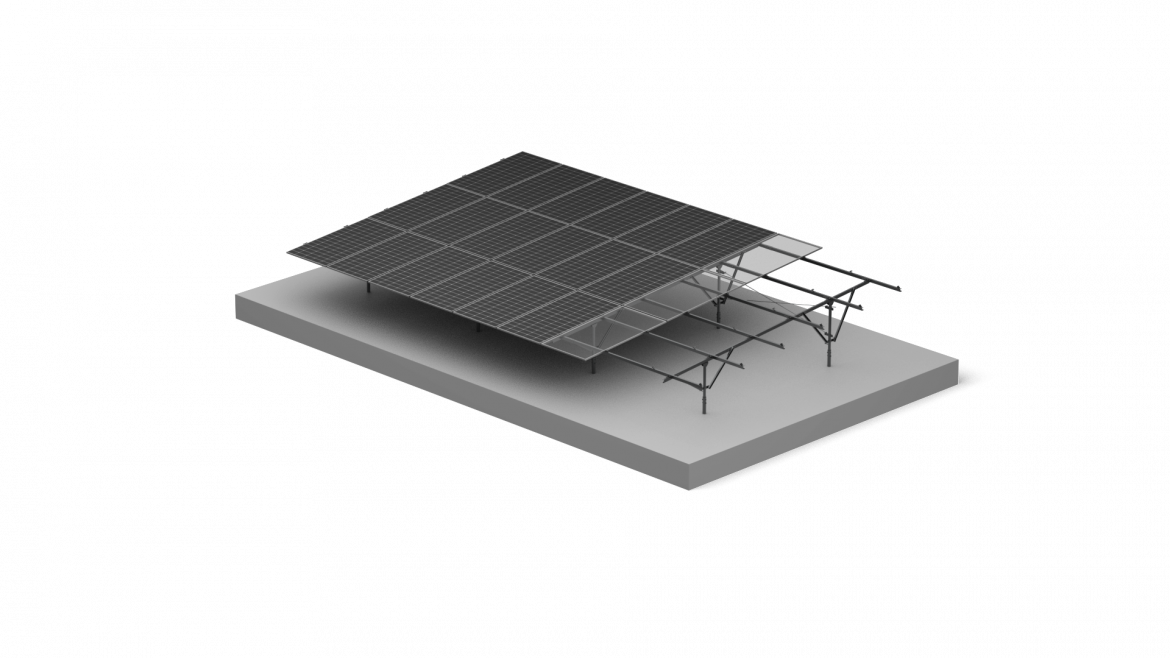

Foundation work is a major component of utility-scale solar project planning. The method chosen to secure the structure to the earth impacts installation timelines, overall costs, and long-term stability. For many projects, the use of a solar ground screw presents a viable alternative to traditional concrete foundations, offering distinct advantages in speed and minimal site disturbance.

Streamlining Installation and Reducing Labor

A significant benefit of the solar ground screw is the potential for a faster installation process. These components are typically installed using specialized machinery, which can drive them directly into the soil without the need for extensive excavation or pouring concrete. This method bypasses the curing time associated with concrete, allowing the racking superstructure to be assembled almost immediately. The pre-assembled design of certain systems further accelerates this process, which can substantially reduce labor hours and related costs on large-scale deployments.

Ensuring Long-Term Stability in the Field

The durability of a solar ground screw is paramount. These components are the anchor points for the entire array and must resist corrosion and subsidence for decades. High-quality versions feature heavy-duty construction with corrosion-resistant plating, engineered to withstand harsh soil conditions and variable weather. This robust design ensures the foundation maintains its grip and structural integrity, providing the industrial-grade stability required for the solar asset’s 25-plus-year lifespan.

The selection of a foundation system is a critical early decision in solar farm development. Opting for an engineered solar ground screw solution from Antaisolar can offer project developers a path to reduced installation time and cost, while still providing the necessary durability and strength for a permanent, large-scale energy generation facility.