Companies in mechanical, thermal, and structural component industries often seek manufacturing methods that balance precision, repeatability, and efficiency. This naturally brings attention to how die casting services operate in real industrial environments. For many procurement teams and R&D engineers, understanding these services helps in selecting the right die casting manufacturer for high-volume metal part production. In this context, Dingmetal serves as a practical example, as their workflow reflects how professional die casting processes support consistent quality, controlled lead times, and stable performance across batches.

Core Processes and Principles of Die Casting

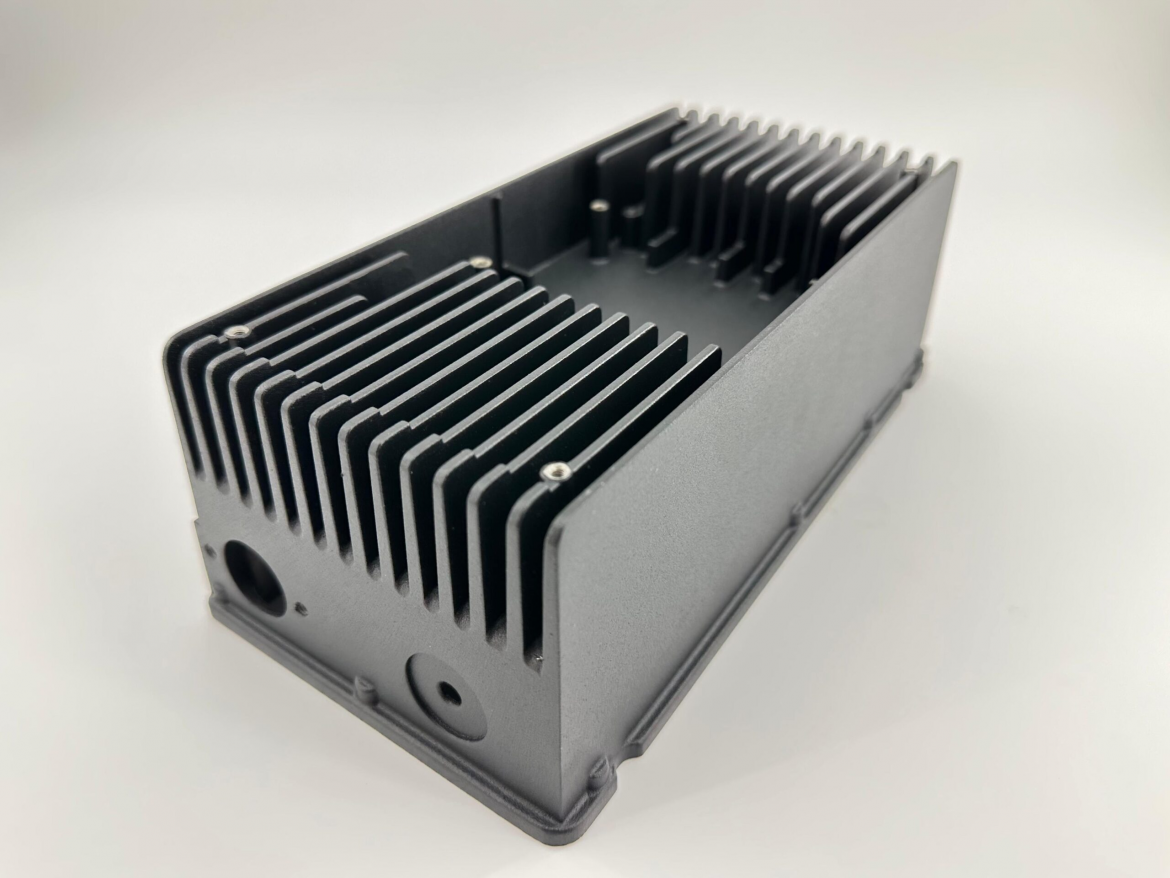

Die casting relies on injecting molten metal into hardened steel molds using controlled high pressure. This principle enables manufacturers to create complex shapes with highly consistent dimensions, which is especially valuable for customers seeking a dependable die cast supplier for ongoing production projects. The rapid cooling within the mold helps components form dense structures and smooth surfaces, minimizing the need for additional machining.

The technique becomes particularly cost-effective when production quantities exceed 1,000 units. At this volume, the initial tooling and NRE costs are spread across larger batches, allowing businesses to benefit from repeatable output and predictable quality. These characteristics make die casting a logical choice for mechanical housings, thermal modules, and precision enclosures used across machinery, electronics, and cooling systems.

Understanding How Professional Service Workflows Operate

In a typical workflow, a die casting manufacturer begins with a design assessment that includes examining draft angles, wall thickness, stress distribution, and the feasibility of filling specific geometries. This stage prevents issues such as trapped air, warping, or insufficient fill during production.

Once the design is approved, production moves into metal melting, injection under high pressure, mold cooling, and part ejection. A reliable die cast supplier continuously monitors temperature stability, metal purity, injection pressure, and cycle timing. These parameters must remain consistent from batch to batch to maintain accuracy across thousands of units. After forming, components undergo inspections such as dimensional checks, structure verification, surface evaluation, and mechanical testing. These steps ensure each part meets performance expectations and can transition smoothly into assembly or integrated system applications.

How Dingmetal Applies These Methods Across Their OEM and ODM Projects

When reviewing real applications, Dingmetal incorporates engineering analysis, advanced die design, stable pressure systems, and controlled thermal management to support various OEM and ODM requirements. Their capabilities suit customers developing structural components, mechanical enclosures, or cooling-related parts that require intricate contours and reliable tolerances.

As a result, many components require minimal machining, helping shorten overall delivery cycles while maintaining predictable quality. They apply structured quality assurance, repeated measurement routines, and consistent metal processing standards to align with the needs of procurement teams and R&D engineers. This approach supports industries where durability, stable geometry, and repeatability are crucial for assembly performance and long-term reliability.

A Clear Understanding Improves Supplier Selection and Project Outcomes

A deeper understanding of how die casting services function allows buyers and engineers to evaluate which manufacturing partner aligns with their project goals. Observing how companies like Dingmetal manage design validation, workflow control, and consistent quality highlights why selecting the right die casting manufacturer or working with a dependable die cast supplier can influence cost, efficiency, and product success. With a clear knowledge of these processes, businesses can plan more effectively and ensure their components meet performance requirements throughout the production cycle.